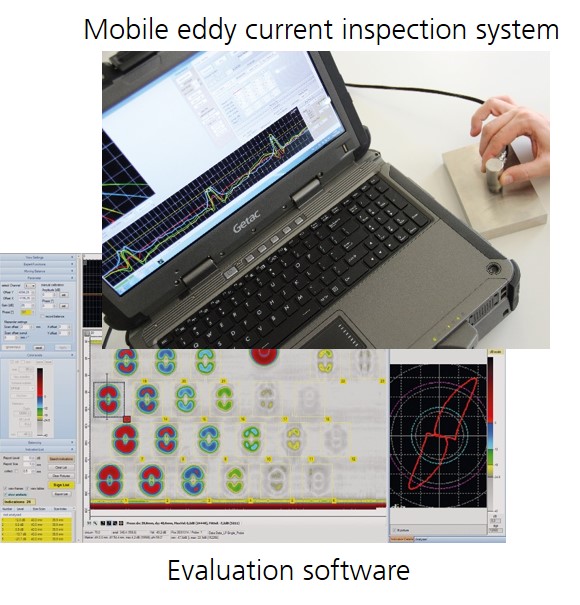

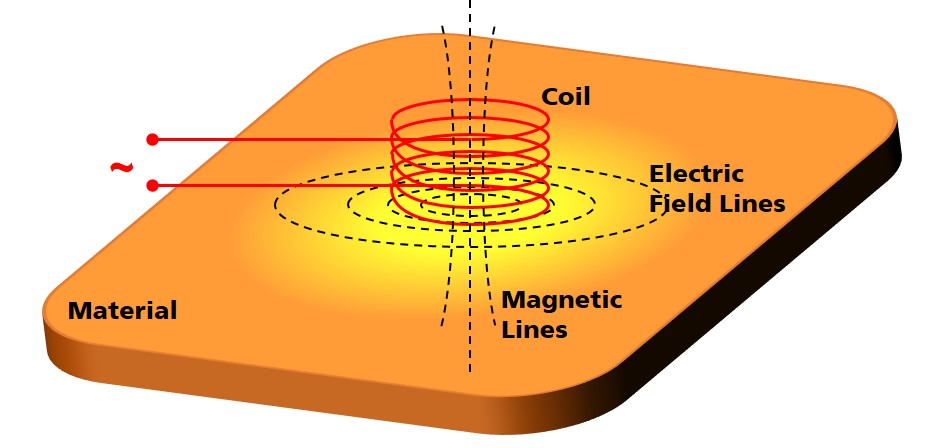

Over the last two decades, electromagnetic methods passed through an extensive technical development up to a degree where - in the frame of nondestructive testing technologies - they have to be labeled as "key technologies".

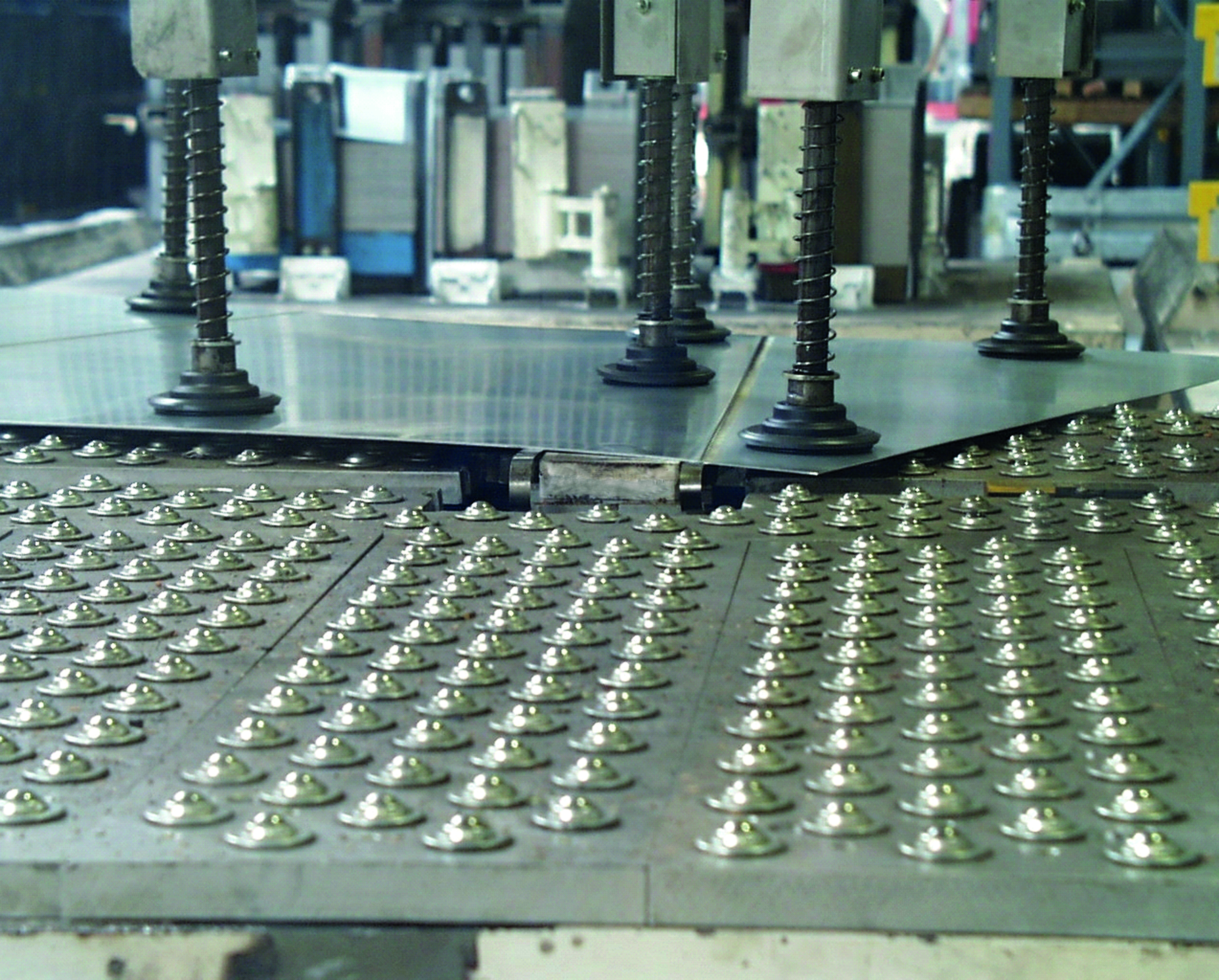

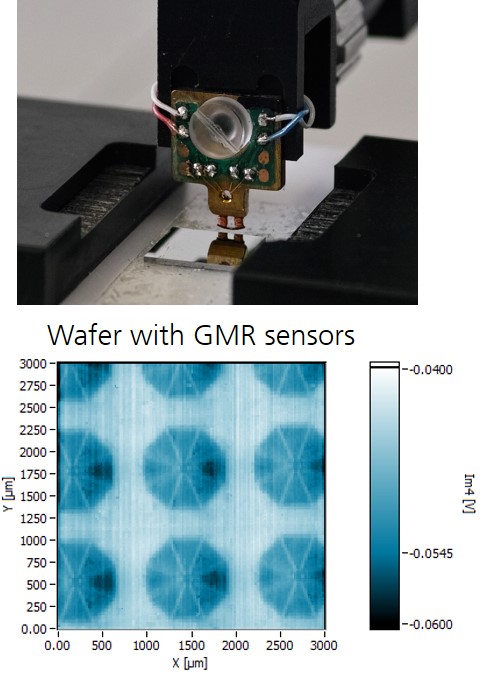

In matters of the upcoming remodeling of industrial high-tech sectors towards "Industrie 4.0" concepts, the embedding of electromagnetic sensors and sensor systems offers forward-looking development potential for the comprehensive digitization and process control of industrial production and processing systems.

Moreover, last decade's developments in automotive industry away from internal combustion engines to electromobility are to be kept in mind. While the inspection of ferromagnetic materials is a matter of course in inspection technology, in the near future development, examination and control of technical magnetic systems will gain considerable economic importance, too.

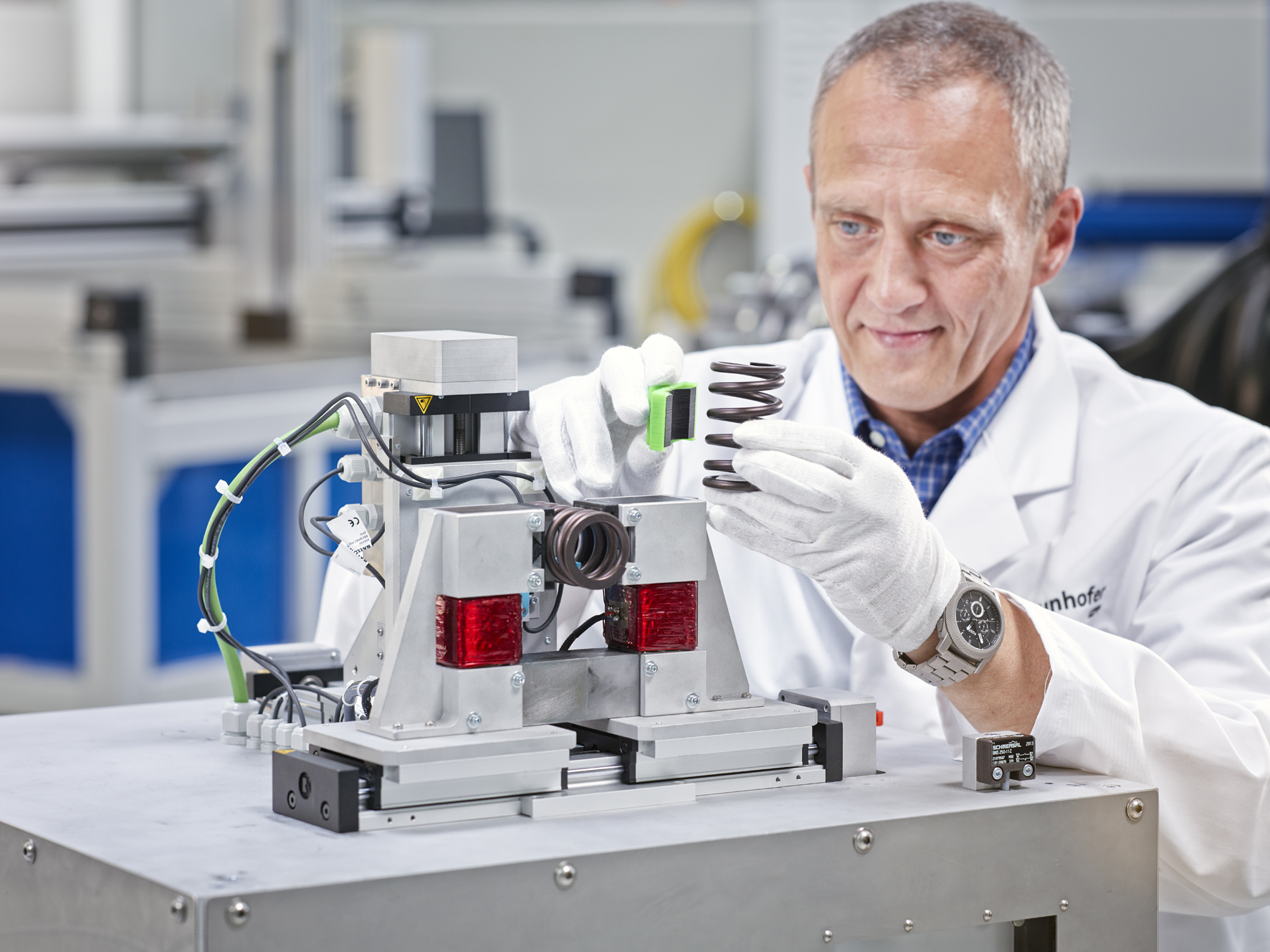

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP